From peeling to pitting, engineered to support you

Industry-leading fruit processing equipment

Our equipment

Our fruit processing machinery is built on a foundation of engineering excellence and operational expertise. Each piece of fruit processing equipment is designed to maximize yield recovery, maintain superior product quality, and deliver reliable performance under demanding production conditions.

Whether you’re processing 100 apples per minute or 1,000 apricots per minute, our machinery solutions scale to meet your operational requirements.

But we don’t just provide equipment. We go beyond with reliable support for every solution we build.

Machinery Solutions

Browse our selection of fruit processing machinery and equipment to see how we can help you optimize your operations, improve product quality, and advance your business. Each piece of fruit processing equipment is backed by Atlas Pacific’s 70+ years of engineering expertise and comprehensive support infrastructure.

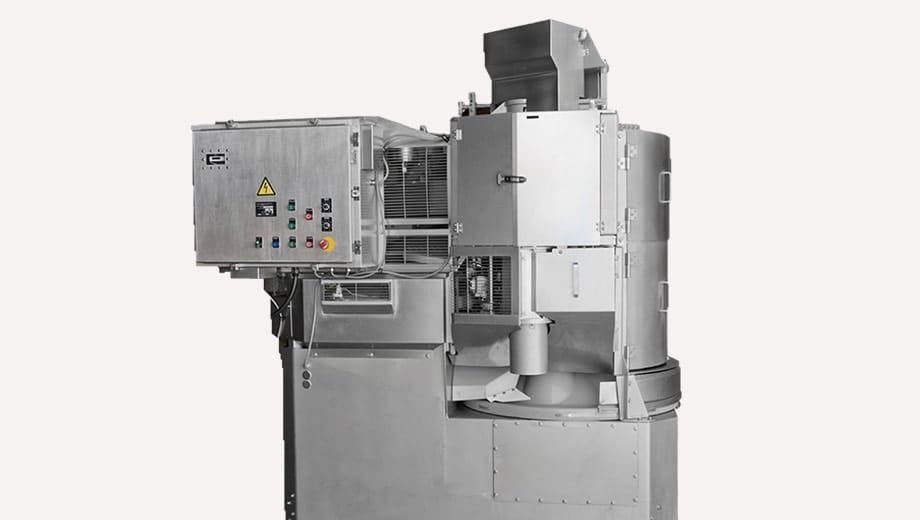

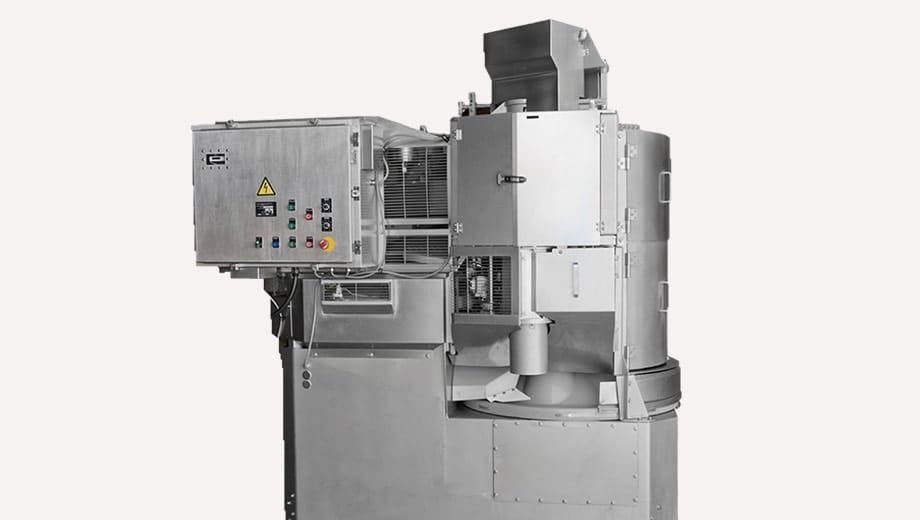

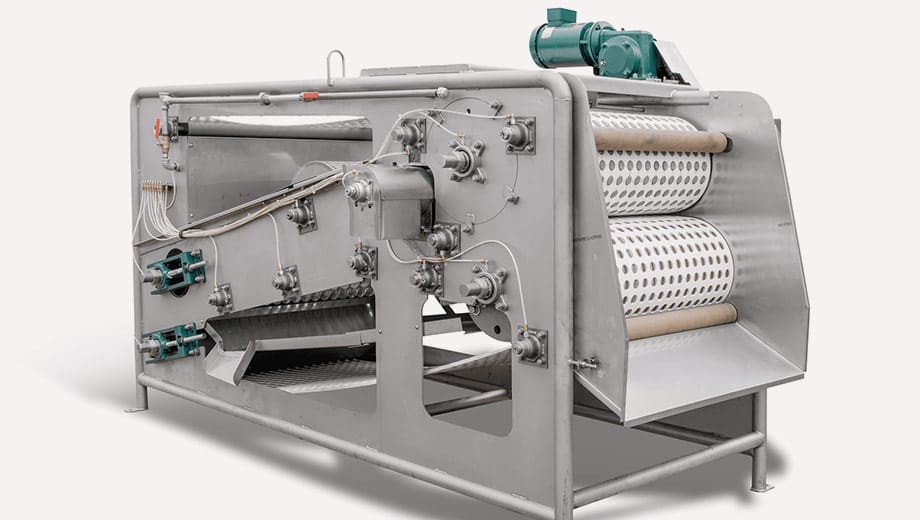

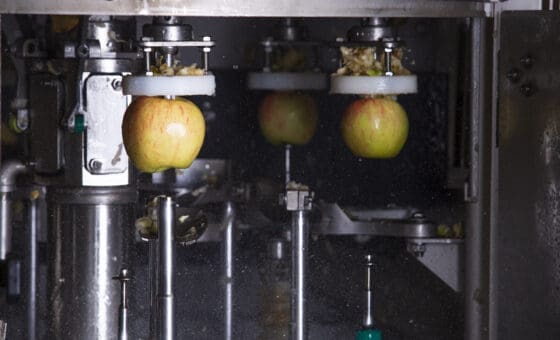

Feed, orient, core and peel at speeds up to 130 apples per minute. Our Apple Peeler is specifically designed to produce the highest yield possible using Sensor Peel technology.

The optional integrated slicer can core and slice at speeds up to 115 apples per minute in several different slice configurations. This Apple Slicer is designed to exceed the demands of the fresh slice apple industry.

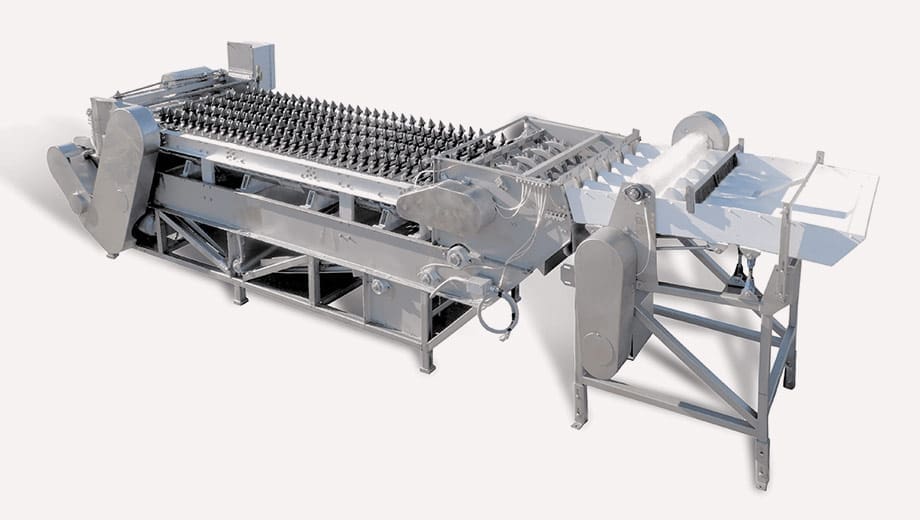

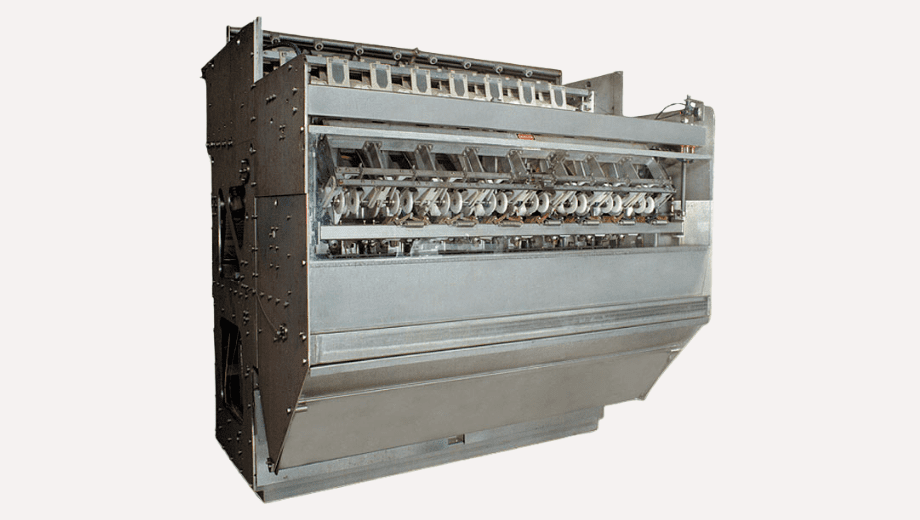

Orient, slice and pit apricots at up to 1,000 pieces of fruit per minute. Our Apricot solutions are ideal for producing grade-pack-quality apricot halves.

Unique in its simplicity, the Atlas Pacific Cherry Stemmer operates with a minimum number of parts, all of them standard and exposed for ease of lubrication and maintenance.

The Peach Spoon Pitter is a state-of-the-art pitter designed to pit both clingstone and freestone peaches.

The Clean Peach Pitter is a stainless steel, water-lubricated, cling and freestone peach pitter that operates up to 91 peaches per minute.

This is the industry standard in live-knife pear peelers for commercial processing. It efficiently peels, cores and slices with minimal skin removal to retain natural flavors and produce higher yields.

Fully automatic, the High-Speed Pear Peeler is designed to maximize pear production and optimize yield recoveries. The eight-lane machine features non-corrosive construction and superior feeding, orienting and peeling capabilities.

Common questions about our fruit processing machinery

Our fruit processing equipment ranges from 91 peaches per minute on our Clean Peach Pitter to 1,000 apricots per minute on our Apricot Pitter and Halver. Apple processing machinery handles up to 130 apples per minute (peeling) or 115 apples per minute (slicing). Specific speeds depend on fruit size, variety, and product format.

Some of our machinery handles multiple varieties (like our peach pitters processing both clingstone and freestone), while other equipment is optimized for specific applications.

All our equipment includes comprehensive support: installation supervision, operator training (multilingual), process consultation, responsive technical support, and access to our global service network. We view every sale as the beginning of a long-term partnership.

Get in Touch

Get in Touch

Have questions about our fruit processing solutions?

Interested in exploring a partnership that opens new opportunities?